To move a vehicle, an internal combustion engine must convert its heat energy to mechanical energy. This mechanical energy goes from the engine to the driving wheel tires by means of a system of connecting rods, shafts and gears. The final factor that moves a vehicle is the amount of traction its tires have on the road surface.

Traction is the ability of a tire to grip the road surface it rolls on. The vehicle’s acceleration rate depends on the power the engine develops and the amount of traction the tires have on the road surface.

Friction is the force which resists movement between two surfaces in contact with each other. To stop a vehicle, brake shoe linings are forced against the machined surfaces of the brake drums, creating friction. This friction produces heat.

The engine converts the energy of heat into the energy of motion - the brakes must convert this energy of motion back into the energy of heat. Friction between brake drums and linings generates heat, while reducing the mechanical energy of the revolving brake drums and wheels. The heat produced is absorbed by the metal brake drums, which dissipate heat by passing it off into the atmosphere. The amount of heat the brake drums can absorb depends on the metal thickness of which they are made. When enough friction is created between brake linings and drums, the wheels stop turning. The final factor that stops a vehicle is not the brakes, but the traction between tires and road surface.

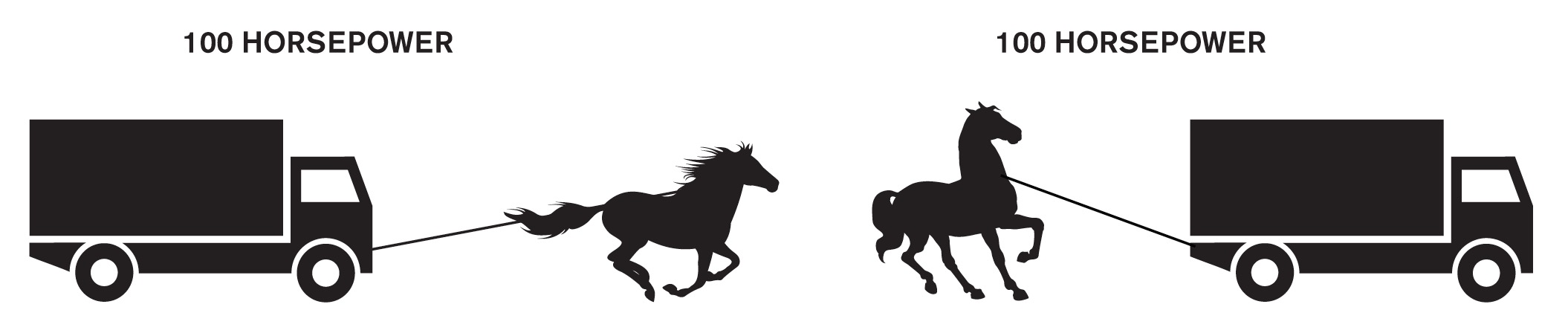

If a 200 horsepower engine accelerates a vehicle to 100 km/h in one minute, imagine the power needed to stop this same vehicle. Not only that, the vehicle might have to be stopped in an emergency, in as little as six seconds (just 1/10 of the time it took to reach 100 km/h).

To stop a vehicle in 1/10 the time it takes to accelerate requires stopping power of 10 times the acceleration power - equivalent to 2,000 horsepower.

If the vehicle had six wheels, each wheel would have to provide 1/6 of the braking power. If one or two wheels had brakes that were not properly adjusted, the other wheels would have to do more than their share of the braking, and that might be more than their brakes were constructed to stand. Excessive use of the brakes would then result in a build-up of heat greater than the brake drums could absorb and dissipate. Too much heat would result in brake damage and possible failure.

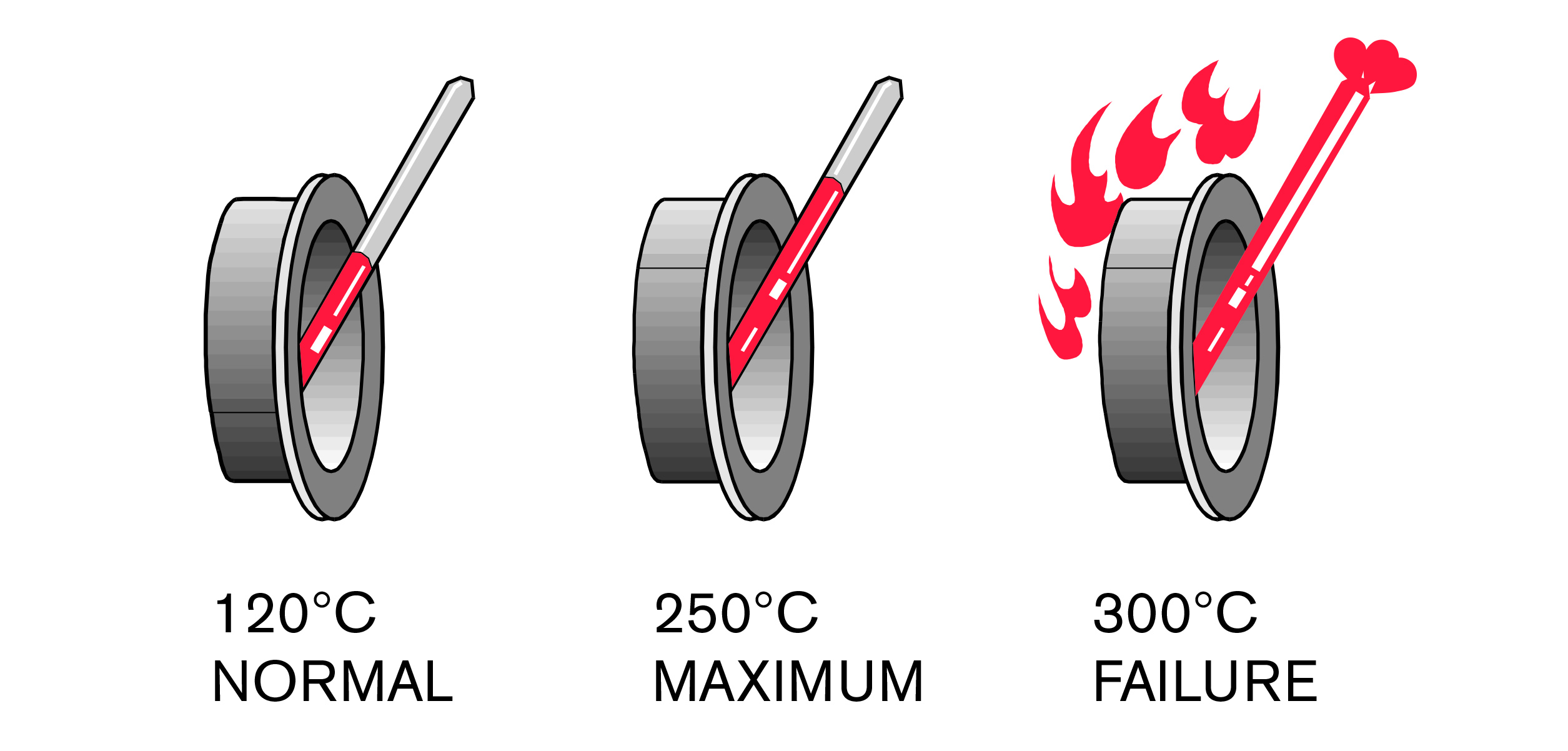

Most brake linings operate best around 120°C and should not exceed 250°C (Fig. 2). It’s important to understand that the power needed to stop generates heat which could ruin the brakes.