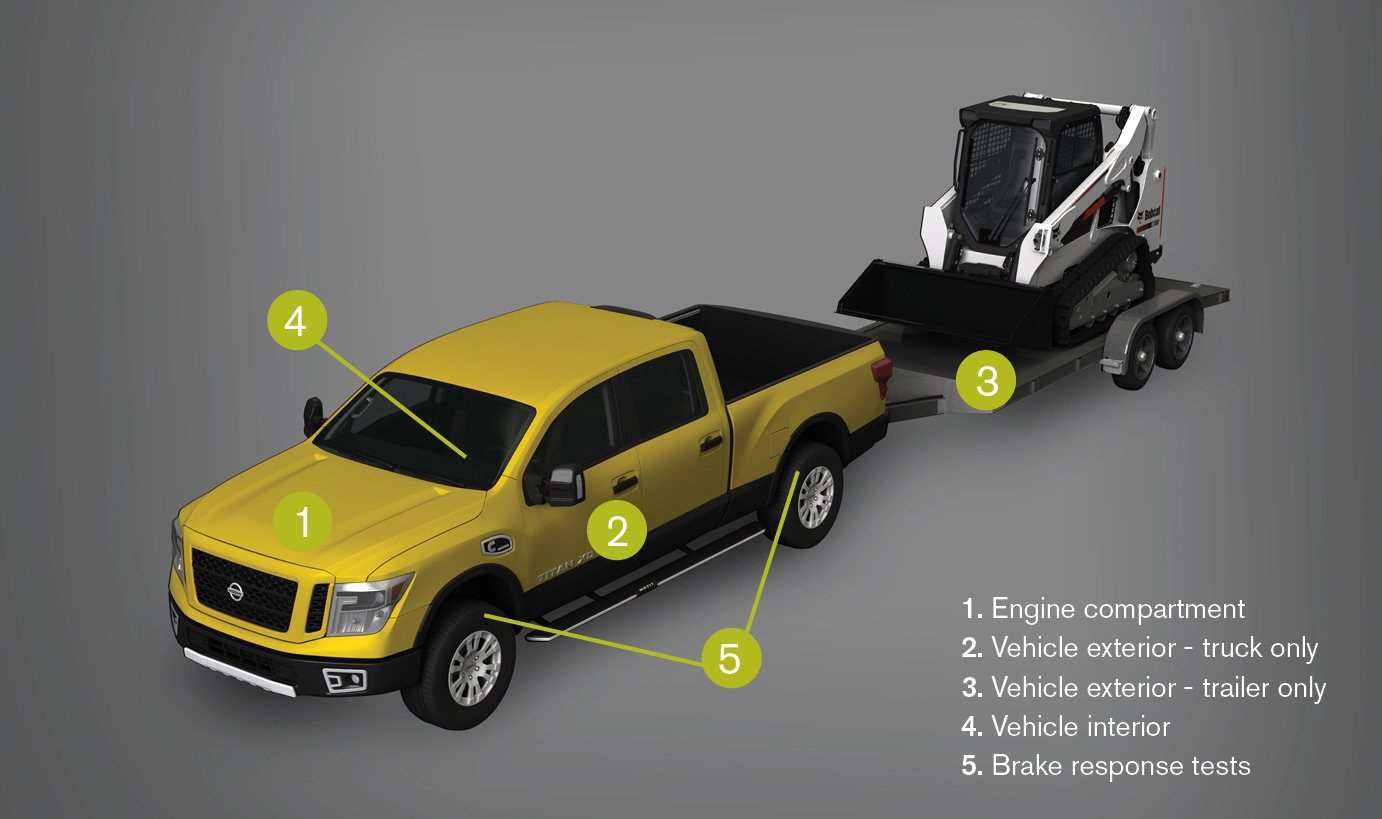

This section applies to two-axle trucks towing a heavy trailer that weighs over 4,600 kg (10,141 lb.) including the load.

Applicable inspection schedules: Schedule 11

Before you begin:

- set the parking brake

- shut off the engine

- block the wheels

1. Engine compartment

Open the engine compartment and make sure the safety lock for the hood is in the locked position, if equipped.

Inspect the following items:

| Fluid levels | All fluids must be at a safe operating level, including:

|

|---|---|

| Belts | Check all drive belts for tension, wear, cracks and fraying. Note: Never check the belts while the engine is running. |

| Hoses | Check all hoses for leaks, fraying, poor connections or damaged hose clamps. |

| Electrical wiring and connections | Check for bare wires or loose connections and make sure wiring is securely attached to the vehicle. |

| Battery | Check for corrosion and leaks. Make sure the battery and the battery cables are secure. |

2. Vehicle exterior - truck only

When conducting a heavy trailer inspection, you need to inspect both the truck and the trailer. The truck and the trailer must be coupled together when conducting the inspection. For simplicity, we will identify the inspection items for the truck and the trailer separately.

If there are multiples of the same item on the vehicle, you must inspect each item the same way. For example, on a truck towing a heavy trailer, there will typically be a minimum of eight tires and rims that need to be inspected individually.

Inspect the following items:

| Headlights | Both the low beam and high beam lights must be working. |

|---|---|

| Hazard lights | Check the operation of all hazard lights on the front, sides and rear of the truck. |

| Signal lights | Check the operation of both the left and right signal lights on the front, sides and rear of the truck. |

| Clearance, marker and identification lights | Where equipped, check that all lights on the top, front, rear and along the sides of the truck are working. |

| Tail lights | Make sure they are working. |

| Brake lights | Make sure they are working. |

| Mirrors | All mirrors must be securely attached to the vehicle and not damaged. |

| Doors | Both front driver side and passenger side doors must open and close properly from the outside. |

| Fuel tank(s) | Fuel cap is on and secure. Tank is secure and straps are not loose. Fuel lines are secure and there is no fuel leaking. |

| Exhaust leaks | Make sure there are no audible or visible signs of leaks. |

| Fluid leaks | Look for fluid leaks underneath the truck. |

| Suspension | All suspension components on each axle must be secure and not damaged, including:

|

| Frame | Where the frame is visible, look for damage or cracks. |

| Tires | Check each tire for:

|

| Rims | Look for damage or cracks. |

| Lug nuts | Look for missing lug nuts. Look for rust or shiny rings around the contact surfaces to indicate a loose lug nut. |

| Coupling devices (fifth-wheel, pintle hitch, draw bar or ball hitch) | Coupling device must be securely attached to the vehicle. Must be properly coupled to the trailer. Must be in the locked position and locked by the applicable locking device such as a pin or jaws of a fifth-wheel. |

3. Vehicle exterior - trailer only

In the above section we identified the inspection items for the truck only. We will now identify the inspection items for the trailer.

Inspect the following items:

| Hazard lights | Check the operation of all hazard lights on the sides and rear of the trailer. |

|---|---|

| Signal lights | Check the operation of both the left and right signal lights on the sides and rear of the trailer. |

| Clearance, marker and identification lights | Check that all lights on the front, rear and along the sides of the trailer are working. Check that all lights at the top of the front and rear of the trailer are working. |

| Tail lights | Make sure they are working. |

| Brake lights | Make sure they are working. |

| Reflective tape | If equipped, all reflective tape along both sides of the trailer must be properly affixed, not damaged and cover at least 50% of the length of the trailer. All reflective tape on the rear of the trailer must be properly affixed and not damaged. |

| Electrical cord | Must be properly connected to the truck. |

| Safety chains | Must be properly connected to the truck. |

| Landing gear and handle | Landing gear must be raised, secure and not damaged. Handle must be stowed in the retaining clip. |

| Frame | Check frame rails and cross members for cracks, bending or damage. |

| Suspension | Check all suspension components on each axle including:

|

| Tires | Check each tire for:

|

| Rims | Look for damage or cracks. |

| Lug nuts | Look for missing lug nuts. Look for rust or shiny rings around the contact surfaces to indicate a loose lug nut. |

| Load or cargo | Make sure the load is secure. |

| Tailgate, cargo or entry doors | Must be closed and secure. All hinges must be secure and not damaged. |

4. Vehicle interior

For the in-cab inspection, some of the items will need to be inspected while the engine is running. We recommend starting the engine before you begin the in-cab inspection.

Inspect the following items:

| Driver seat | Make sure the seat is secure and properly adjusted for you. |

|---|---|

| Driver seat belt | Fasten and unfasten seat belt to make sure it works properly. |

| Mirrors | All mirrors must be clear, unobstructed and not damaged. Make sure all mirrors are properly adjusted for you. |

| Windshield | Must be clear, unobstructed and not damaged. |

| Windshield wipers and washer | Check the wipers for damage and make sure they wipe properly. Turn on the windshield washer to make sure it works properly. |

| Windows | Side and rear windows must be clear, unobstructed and not damaged. |

| Doors | Both front driver side and passenger side doors must open and close properly from the inside. |

| Steering | Check for excessive free play. |

| Horn | Make sure it is working. |

| Instrument panel | Make sure there are no warning lights present. Turn on the left and right signals, hazard lights and high beams to make sure the indicator lights are working properly. |

| Gauges | Engine must be running. Identify each gauge and make sure each gauge is in its normal operating range. |

| Switches | Engine does not have to be running, but the key must be turned on. Identify each switch and make sure each switch is in its normal operating position. |

| Heater, defroster and fan speed | Make sure all temperature controls work and it switches between the heater and defroster positions. Check the fan speed in both the heater and defroster positions. Use your hand to physically check for air blowing out of the vents. |

| Fire extinguisher | Must be present if commercial vehicle is registered in Class LV, A, C or D, wider than 2,060 mm and used for business or commercial purposes. Must be secure and properly charged. |

| Flares, reflectors or triangles | A minimum of three flares/reflectors must be present if vehicle is wider than 2,060 mm and being operated outside corporate limits of an urban municipality. |

5. Brake response tests

Before driving anywhere, it is important to make sure that your brakes work. This section will explain how to test both the service and park brakes for both the truck and the trailer.

Remove the blocks and test the following items:

| Trailer breakaway switch | Disconnect the electrical cord from the truck. Remove the pin on the breakaway switch and try to gently pull ahead to test the emergency application of the trailer brakes. Replace the pin for the breakaway switch and reconnect the electrical cord to the truck. |

|---|---|

| Truck park brake | Apply the truck park brake and try to gently pull ahead to test the application of the truck park brake. |

| Trailer brake hand control | Release the truck park brake, drive slowly ahead and apply the trailer brakes using the hand control, if equipped. |

| Truck foot brake | Release the hand control, drive slowly ahead and apply the foot brake. |

Footnotes

- Applies to commercially licensed heavy trailer combination units with a registered gross vehicle weight of more than 11,794 kg. ↩